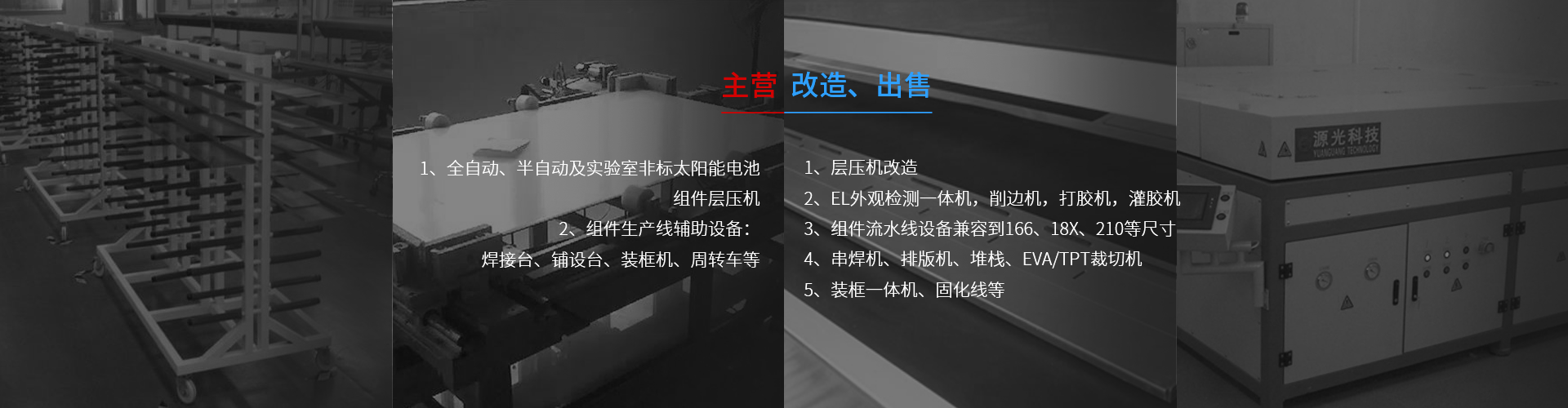

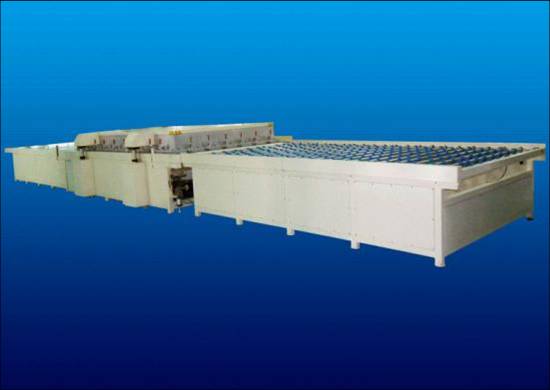

第二代全自動層壓機

1.智能化溫度控制系統,使得溫度更加均勻,更加易于對溫度的設定與控制。

2.層壓壓力可調,且可以根據工藝調壓,使得組件的質量更加優良。

3.可連續24小時高溫工作。

4.先進的觸摸屏操作平臺,使得操作更加直觀、易懂。反應更加迅速,性能更加穩定,故障率進一步降低。

5.采用完全人性化和智能化的系統操作流程,整臺設備配備有多處檢測開關,在正常的生產工作中,操作人員僅需將組件放在輸入平臺上,按動輸入開關即可,此設備將自動輸入組件到主機進行封裝、固化,自動將其輸出到指定位置等待操作員進行下一工序的處理,并自動進行下一循環工作。

6.三級聯動結構緊湊,輸入、輸出采用帶式結構,保證了待壓組件的平穩性要求.

7.出料級采用風冷形式,提高了組件生產效率. 1. Intelligent temperature control system makes the temperature more homogeneous and easier to set and control.

2. Laminating pressure is adjustable and can be adjusted according to the process, which makes the quality of modules better.

3. It could work continuously in high temperature for 24 hours.

4.The advanced touch screen operating platform makes it more intuitive to operate, makes it respond more quickly, make the performance more stable and the failure rate is further reduced.

5. Applying a fully humanized operating procedure. The equipment is equipped with many detection switches. In the normal production, operators will only be required to put the modules on the heating platform and press the cover switch. The equipment will automatically laminate, cure and open cover automatically and wait for operator to start the next procedure.

6. Compact three-level linkage structure , and the belt structure is applied for the input and output procedure to make sure the modules to be laminated go smoothly.

7.The output grade is wind cold structure, to improve module production efficiency.